Beam Roll Forming Machine

Beam Roll Forming Machine

Beam Roll Forming Machine

Beam Roll Forming Machine

Beam Roll Forming Machine

TECHNICAL PARAMETER

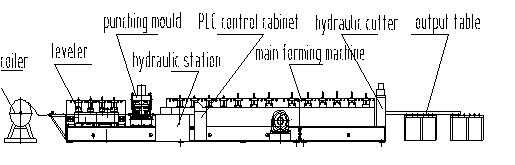

FLOW CHART

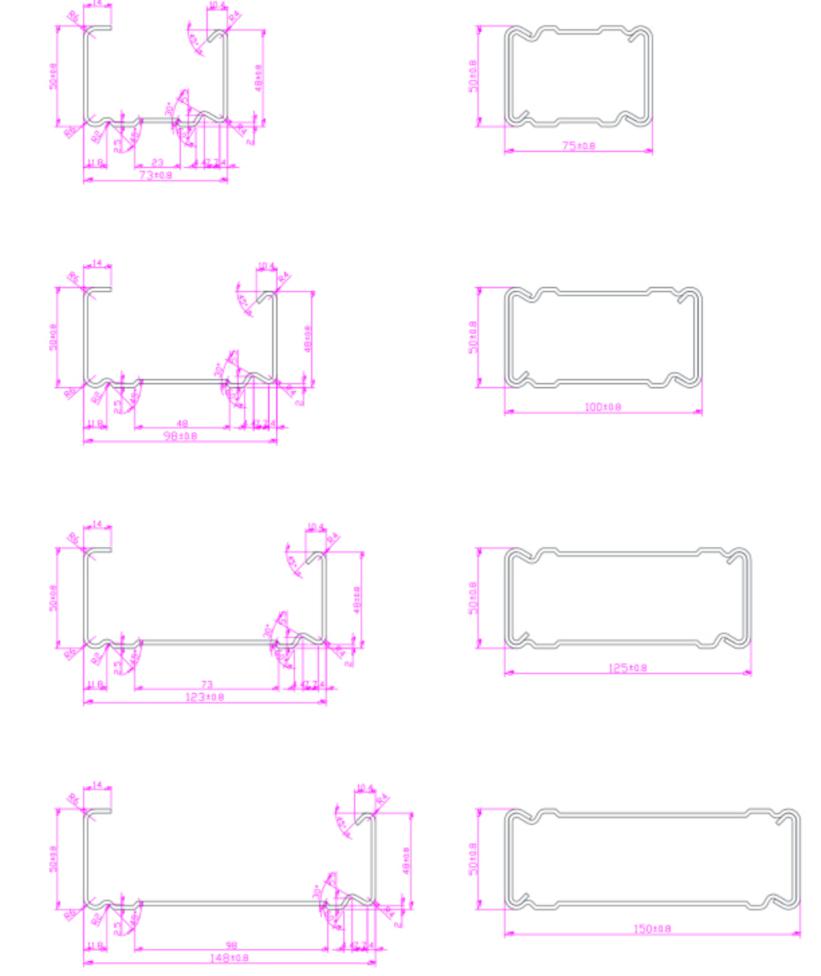

PROFILE

APPLICATION

A.hydraulic decoiler:

1)Inner diameter of de-coiler: 508mm, 610mm

2)Coil width: 625mm

3)De-coiler capacity: 5T

4)Main motor power: 3KW

B.pinching feeding and leveling device

1)Function: It is used to release the head of coil and make the coil straight and flat after de-coiling which also ensure high speed and high accuracy.

2)Rollers for leveling: 7 rollers, assures the levelness.

C.punching device

1)Punching before forming controlled by PLC. punch the LOGO of customer’s request.

D.Main roll forming machine

1)Roller station: about 26 stations up to our final design

2)Two set of rollers: 1350 lip angle is considered for box beam and 900-1000 lip angle is used for C purlin (Three set of stations may need to be changed for purlin lip angle adjustments - as per final designs number of rollers may be different)

3)Two common ribs on web is considered for all section.

4)Forming speed: 8m/min (without punching and cutting)

5)Machine form: single stand with chain transmission

6)Material of roller adopts high-quality alloyed bearing steel GCR15

7)Quenching hardness of roller: HRC580-600

8)Material of shaft: 40Cr

9)Diameter of roller shaft: ¢70㎜

10)Thickness of steel coil: 1.0-2.5mm (the range is a bit bigger, sometimes it will occurs tolerance after interlocking )

11)Main motor power: 11kw

12)Steel coil material: S315MC – σs≥315Mpa

13)Adjustable type of width of the forming machine: using the linear lead rail, lead screw, horizontal manual adjustment for all the profiles required.

14)14mm length lip for 90, 95, 105, 125, 135,160 box sections.

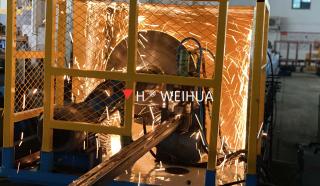

E.Hydraulic cutting device

1)Material of blade: Cr12

2)heat treatment of cutting blade: (HRC58°-62°)

3)hydraulic cutting with stopping machine, no waste

F.Computer controlling cabinet

1)Computer adopts PLC,Omron.

2)Transducer: Holip

3)Computer operating board adopts WENVIEW

4)Voltage: 415 V, 50 Hz, 3Phase (according to customer’s requirement)

G.Hydraulic station

1)motor of hydraulic station:5.5kw

2)hydraulic oil pump:gear pump CB-E314

H.Box interlocking machine

1)Roller stand: 6 stations up to our final design

2)Power: 3kw

1)Inner diameter of de-coiler: 508mm, 610mm

2)Coil width: 625mm

3)De-coiler capacity: 5T

4)Main motor power: 3KW

B.pinching feeding and leveling device

1)Function: It is used to release the head of coil and make the coil straight and flat after de-coiling which also ensure high speed and high accuracy.

2)Rollers for leveling: 7 rollers, assures the levelness.

C.punching device

1)Punching before forming controlled by PLC. punch the LOGO of customer’s request.

D.Main roll forming machine

1)Roller station: about 26 stations up to our final design

2)Two set of rollers: 1350 lip angle is considered for box beam and 900-1000 lip angle is used for C purlin (Three set of stations may need to be changed for purlin lip angle adjustments - as per final designs number of rollers may be different)

3)Two common ribs on web is considered for all section.

4)Forming speed: 8m/min (without punching and cutting)

5)Machine form: single stand with chain transmission

6)Material of roller adopts high-quality alloyed bearing steel GCR15

7)Quenching hardness of roller: HRC580-600

8)Material of shaft: 40Cr

9)Diameter of roller shaft: ¢70㎜

10)Thickness of steel coil: 1.0-2.5mm (the range is a bit bigger, sometimes it will occurs tolerance after interlocking )

11)Main motor power: 11kw

12)Steel coil material: S315MC – σs≥315Mpa

13)Adjustable type of width of the forming machine: using the linear lead rail, lead screw, horizontal manual adjustment for all the profiles required.

14)14mm length lip for 90, 95, 105, 125, 135,160 box sections.

E.Hydraulic cutting device

1)Material of blade: Cr12

2)heat treatment of cutting blade: (HRC58°-62°)

3)hydraulic cutting with stopping machine, no waste

F.Computer controlling cabinet

1)Computer adopts PLC,Omron.

2)Transducer: Holip

3)Computer operating board adopts WENVIEW

4)Voltage: 415 V, 50 Hz, 3Phase (according to customer’s requirement)

G.Hydraulic station

1)motor of hydraulic station:5.5kw

2)hydraulic oil pump:gear pump CB-E314

H.Box interlocking machine

1)Roller stand: 6 stations up to our final design

2)Power: 3kw

Related Product

Top